- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

OEM/ODM Manufacturer Triple Roller Mill - TC roll rings products for steel rolling mill machinery – Jinyehong

OEM/ODM Manufacturer Triple Roller Mill - TC roll rings products for steel rolling mill machinery – Jinyehong Detail:

Product Introduction

cemented carbide roll rings (also known as tungsten carbide roll ring) possesses good thermal conduction property. Compared with other materials,it is much better in terms of heat-resistance, wear-resistance and strength. What ’s more,its hardness reduces a little under the condition of high temperature. So, the cemented carbide roll rings is invented with the ap-pearance of high speed wire rod mill.With the development and improvement, it is widely applied in the production of high speed wire, bar and deformed steel bar.

As far as the material for our products,there are two series as Wc-Co and Wc-Co-Ni-Cr which possess the good compre-hensive mechanical properties. The bending strength and impact toughness reach 2200 Mpa and(4-) x106J/ m’respectively.Its hardness and wear resistance come from tungsten carbide (Wc) while the toughness and strength depend on the binding agent (Co-Ni-Cr).At present, the finishing mill is generally composed of 8- 10 stands. Because of the big size of fracture surface of rolled part, the collar on the front stands of finishing mill may resist heavy duty and strong impact. Thus, the high hardness and good thermal fatigue resistance are the primary factors, which are prior to wear-resistance.While there is low load and impact for therear stands, we shall pay more attention to the wear-resistance and thermal fatigue resistance of roll rings. At present,the finishing mill is generally composed of 8- 10 stands.Because of the big size of fracture surface of rolled part, the collar on the front stands of finishing mill may resist heavy duty and strong impact. Thus, the high hardness and good thermal fatigue resistance are the primary factors, which are prior to wear-resistance. we shall pay more attention to the wear-resistance and thermal fatigue resistance of roll rings.

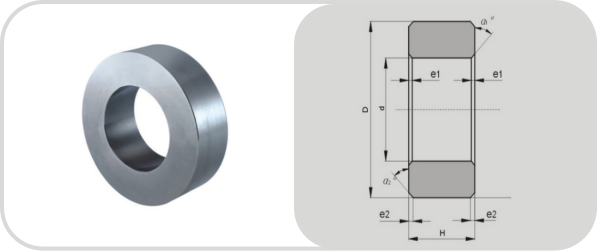

Description of Tc Ring

|

Rang of O.D.(mm) |

Rang of l.D.(mm) |

Rang of height(mm) |

|

145-450 |

87-280 |

62-150 |

Tungsten carbide roll

Range of outer diameter: 154-450mm

Range of inner diameter: 87-280mm

Range of height: 62-150mm

Table of Specification of Finished Rolls

|

Tolerances allowable for the O.D.,I.D, and Height of roll rings(mm) |

||||

|

TYPE |

OD≤200 mm |

OD > 200mm |

||

|

Better Grade |

Normal Grade |

Better Grade |

Normal Grade |

|

|

Tolerance of OD |

±0.020 |

±0.050 |

±0.030 |

±0.050 |

|

Tolerance of ID |

+0.020 |

+0.035 |

+0.025 |

+0.050 |

|

Tolerance of H |

±0.025 |

±0.100 |

±0.050 |

±0.100 |

| Main Grade for TC metal seal mechanical face ring with high density | ||||

| Grade | Density (g/cm³) | Hardness (HRA) | T.R.S(Mpa) | Application Recommended |

| YG4C | 15 | 89.5 | 1800 | Mainly used as small buttons for percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG6 | 15.8 | 89.5 | 1700 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG8 | 14.7 | 88.5 | 2300 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG13C | 14.3 | 86 | 2500 | Mainly used as the inserts and buttons of tricone bits rotary-percussive bits and heavy rock drill bits to cut medium-hard and hard formations. |

| YG15 | 14 | 86.5 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations.v |

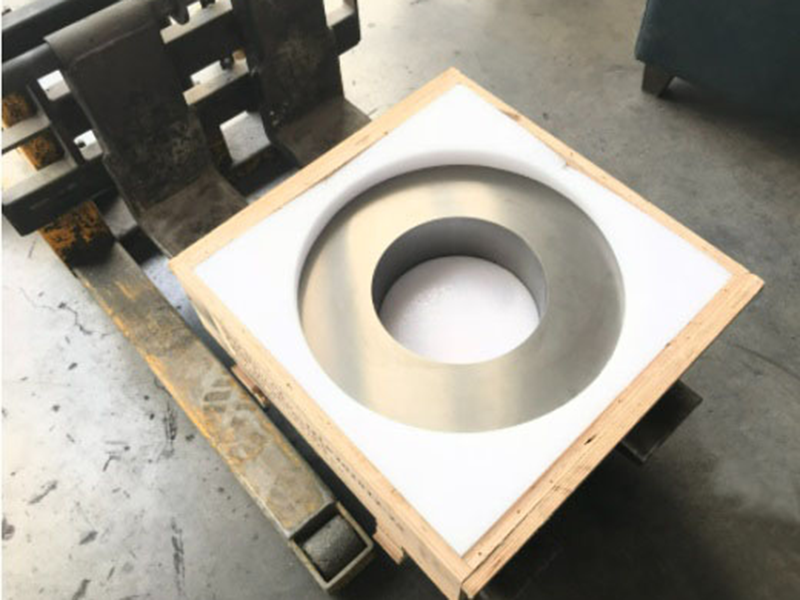

Packing & Delivery

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for OEM/ODM Manufacturer Triple Roller Mill - TC roll rings products for steel rolling mill machinery – Jinyehong , The product will supply to all over the world, such as: Mombasa, Australia, Saudi Arabia, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!