- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

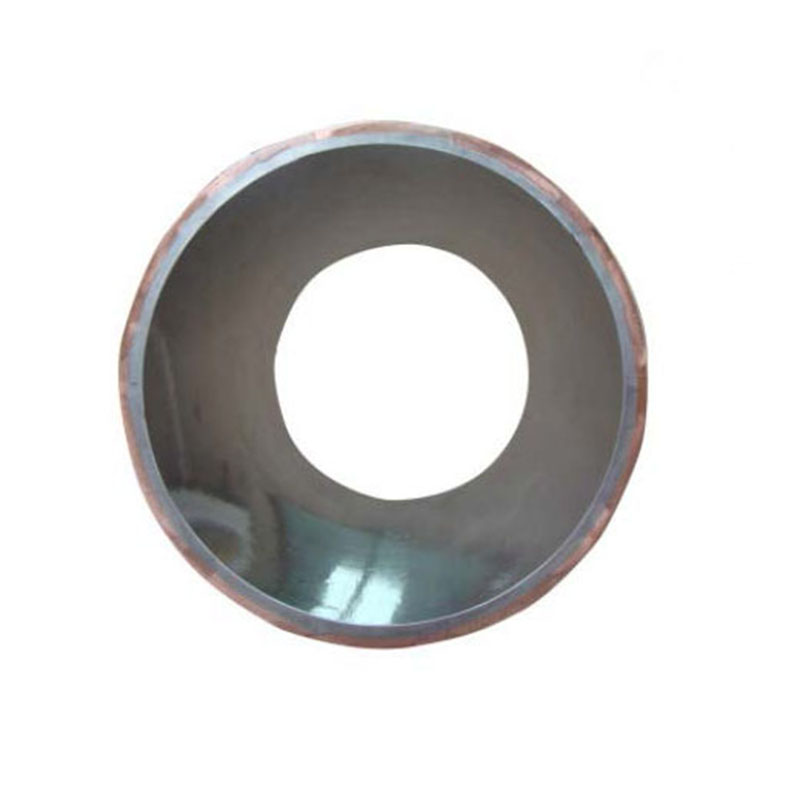

OEM Customized Three High Rolling Mill - Working rolls for mill rolls – Jinyehong

OEM Customized Three High Rolling Mill - Working rolls for mill rolls – Jinyehong Detail:

Product Description

|

Product Name |

Hot Strip Mill Work Roll |

|

Process |

Vertical Centrifugal Cast |

|

Material |

High Chrome Steel, High Speed Steel. Alloy Steel , Enhanced High Chrome Iron |

|

Color |

Nickel White |

|

HRC |

41-45 |

|

Brand |

BJMMEC |

|

Usage |

Convention Hot Strip Mills, Thin Slab Compact Strip Mills., |

|

Roll Grade |

MOC |

Application |

|

URMA |

High Chrome Steel |

Roughing stands |

|

STELLA |

Semi High Speed Steel |

Roughing stands |

|

SDSII |

Forged High Alloy Steel |

Roughing stands |

|

SPECRA R |

High Speed Steel |

Roughing stands |

|

CRONA / CRONA TT |

High Chrome Iron |

Finishing stands F1-3(4) |

|

CICRA |

Enhanced High Chrome Iron |

Finishing stands F1-3(4) |

|

SPECRA F/ HSS #3 |

High Speed Steel |

Finishing stands F1-3(4) |

|

ICRA |

Indefinite Chill |

Finishing stands F4-6(7) |

|

MICRA/APEX |

Enhanced Indefinite Chill |

Finishing stands F4-6(7) |

|

VICTURA |

Twin Alloy Steel |

Finishing stands F4-6(7) |

| Manufacture drawing | ✓ |

| Process schedule with ETD date | ✓ |

| QC checking of each process | ✓ |

| Checking report | ✓ |

| Photos &videos of each process | ✓ |

| Photos &videos of each process | ✓ |

| Warranty Time | ✓ |

| The third party Checking | ✓ |

Our Advantage

(1) Over 20 years experiences in manufacturing precision large nonstandard heavy machinery spare parts.

(2) Having five standardized workshops, which are hoisting hook 150 Tons.

(3) Vertical well electric furnace heat treatment – Max. DIA is 6 meter, Max. Depth 9 meters.

(4) Five senior engineers in forging/ heat treatment fields.

(5) OEM & ODM can provided, specialized e-commerce and technical team can provide online service.

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for OEM Customized Three High Rolling Mill - Working rolls for mill rolls – Jinyehong , The product will supply to all over the world, such as: Sierra Leone, United Arab Emirates, Germany, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!