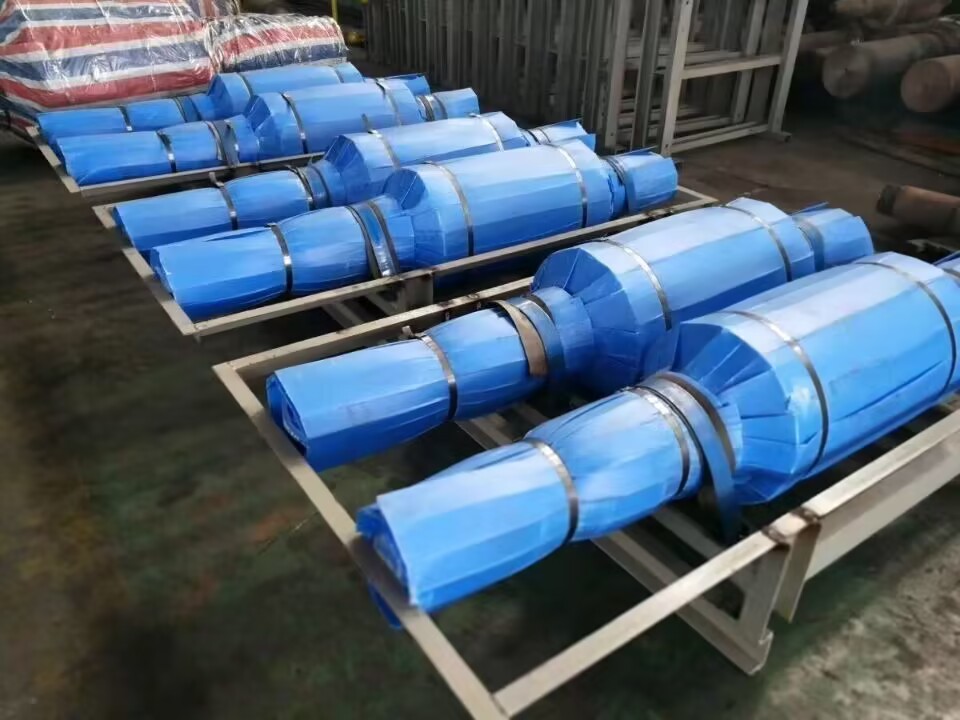

Rolls are an essential component in the hot rolling mill process, playing a crucial role in shaping and forming metal into various products. Among the different types of rolls used in this process, forged roll, work roll, backup roll, and support roll are the key ones that contribute to the efficiency and quality of the hot rolling mill.

Forged rolls are manufactured through a process of shaping and compressing metal under high pressure, resulting in a dense and durable roll. These rolls are known for their strength and ability to withstand the extreme conditions of hot rolling mills, making them ideal for the demanding tasks involved in the process.

Work rolls are another vital type of roll used in hot rolling mills, responsible for applying pressure to the metal to deform and shape it according to the desired specifications. These rolls are subjected to high loads and temperatures, requiring them to have excellent wear resistance and thermal stability to ensure consistent performance.

Backup rolls provide support and balance to the work rolls, helping to maintain the stability and precision of the rolling process. These rolls are designed to withstand the immense forces exerted during the hot rolling of metal, making them an indispensable component in ensuring the quality and accuracy of the final product.

Support rolls, as the name suggests, provide additional support to the work and backup rolls, contributing to the overall efficiency and effectiveness of the hot rolling mill. These rolls are designed to handle the lateral forces and ensure proper alignment of the other rolls, thereby enhancing the overall performance of the rolling process.

In conclusion, the various types of rolls, including forged rolls, work rolls, backup rolls, and support rolls, are integral to the successful operation of hot rolling mills. Their unique characteristics and functions contribute to the overall quality, efficiency, and precision of the metal shaping process, making them indispensable components in the manufacturing industry.

Post time: Aug-30-2024