- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

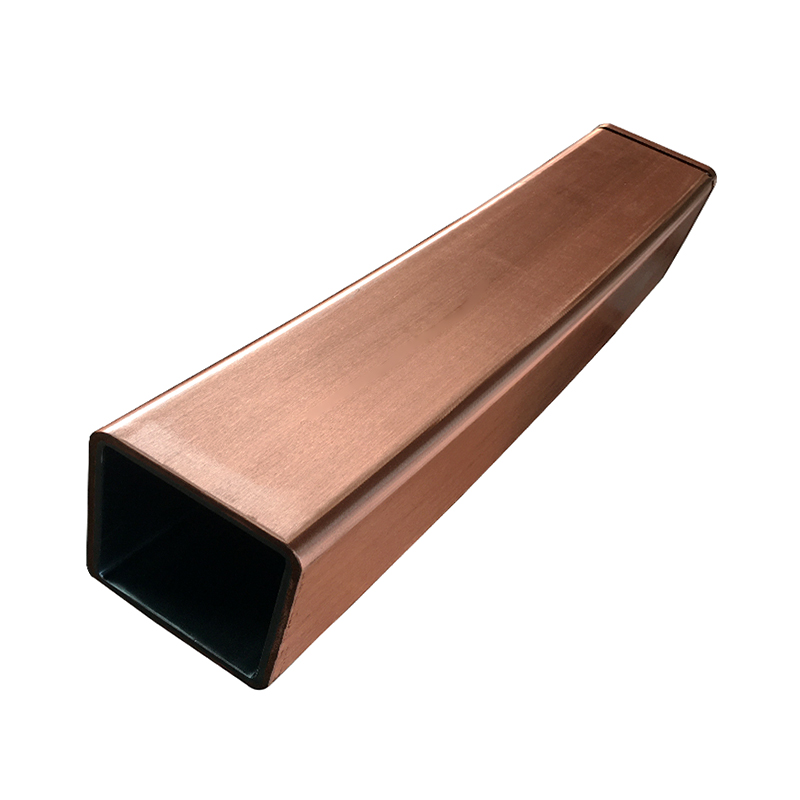

Manufacturing Companies for Copper Mould Tube Dealers - Non-standard Copper Mould Tube – Jinyehong

Manufacturing Companies for Copper Mould Tube Dealers - Non-standard Copper Mould Tube – Jinyehong Detail:

Product Introduction

The continuous casting machine is mainly composed of tundish, crystallizer, oscillator mechanism, regid dummy bar, secondary cooling segment, withdrawal straightening unit, hydraulic sawing torch cutting machine, cross transfer zone, and walking beam cooling bed. Billet caster can also be desigend for quickly transfering hot billet to rolling mills.

In the process of producing various kinds of steel products in iron and steel plant, the ladle with refined molten steel is transported to the rotary turret. After the ladle turret is rotated to the pouring position, the molten steel is injected into the tundish, and then the molten steel is distributed to each crystallier Assembly copper mould tube by the tundish nozzle.

Copper mould tube is one of the core equipments of ccm continuous billet caster. It makes high temperature liquid steel solidify and crystallize rapidly to form steel castings. After electromagnetic induction stirring, the liquid steel in the copper mould is cooled and shaped, and then the casting is pulled out, and then the slab is divided into predetermined length by flame cutting machine ( Torch Cutting Machine).

The main components of the automatic control system for continuous casting include the speed control of casting roller, the control of mold vibration frequency, the control of fixed length cutting and other automatic control technologies.

Production Process

Melting & Casting — Hot Extrusion/Forging — Cold Drawing — Tapering — Machining — Electroplating — Machining after Electroplating — Final Inspection — Packing

Our Service and Target

(1) To provide mould tubes with optimal physical and mechanical properties to customers’ specifications, mould tube products are supplied of the following materials:

Cu-DHP: Normally used for mould tubes section size below 180x180mm and round tubes below Dia.150mm.

Cu-Ag: Normally used for mould tube section size above 180x180mm and round tubes above Dia.150mm

Cu-Cr-Zr: Normally used for beam blank mould tubes

These materials have different levels of hardness and thermal conductivities. We are highly experienced in choosing proper materials to meet the specific demands in heat resistance and thermal conductivities of customers’ applications.

(2) The target of our work is to improve our technological capacities to be in the interest of the customers .For this purpose ,we have been dedicated to new products development .we established R & D department for new alloys ,optimized copper taper and better anti-wearing coating .Our physical and chemical laboratories are equipped with advanced analysis and inspection systems which provides strong guarantee for the quality of our products.

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Manufacturing Companies for Copper Mould Tube Dealers - Non-standard Copper Mould Tube – Jinyehong , The product will supply to all over the world, such as: Armenia, Amsterdam, Egypt, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.