- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

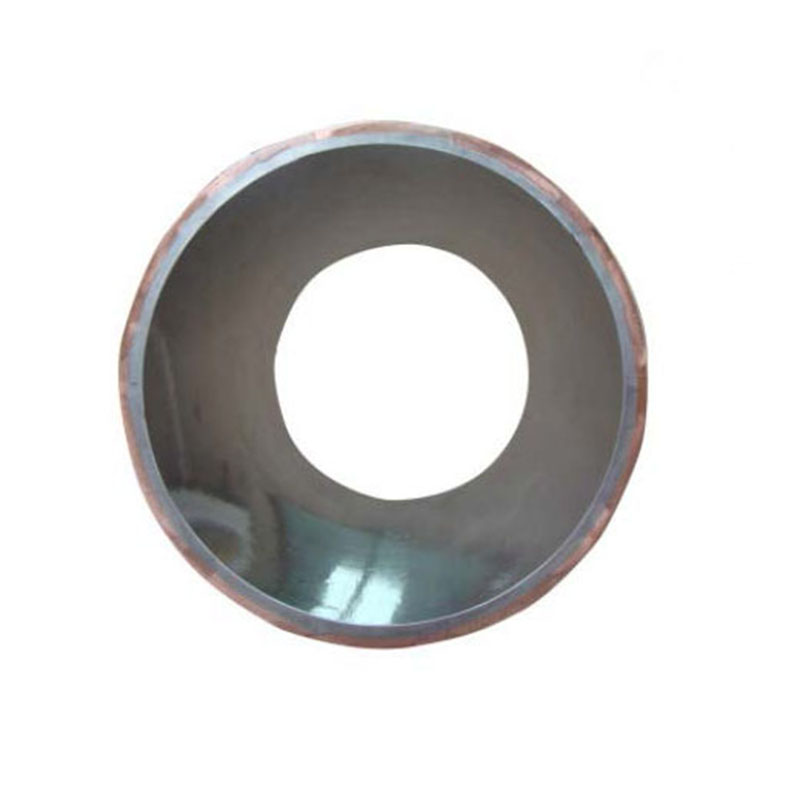

Manufacturing Companies for Copper Mould Tube Dealers - Multi Ni+Cr+Co Coating Square Mould Tube – Jinyehong

Manufacturing Companies for Copper Mould Tube Dealers - Multi Ni+Cr+Co Coating Square Mould Tube – Jinyehong Detail:

Product Introduction

Copper mould tube is one of the core equipments of ccm continuous billet caster.It makes high temperature liquid steel solidify and crystallize rapidly to form steel castings. After electromagnetic induction stirring, the liquid steel in the copper mould is cooled and shaped,and then the casting is pulled out, and then the slab is divided into predetermined length by flame cutting machine ( Torch Cutting Machine).The main components of the automatic control system for continuous casting include the speed control of casting roller, the control of mold vibration frequency, the control of fixed length cutting and other automatic control technologies.

Supply Ability

5000Pieces /per year

✷We supply high quality and durable copper mould tube with most competitive price and prompt delivery.

✸Our Copper Mould Tube meet ISO9001 standards,high precision and meet hardness requirement, perfect taper and coated layer.

✹ We have complete facilities to process every copper mould tube,galvanize plating,hardness testing to provide accurate Chromium plating to the Mould Tubes to achieve high performance in heat resistance.

✹ We manufacture thousands pieces of copper mould tube every month and supply to several biggest Steel Group in China which proved that our product is most trusted and satisfy by our customers.

|

Square billet crystallizer copper tube specification |

||

|

Case section |

Casting machine radius |

Product length |

|

70×70 |

R=3000-5000 |

L=812-850 |

|

80×80 |

R=3000-5000 |

L=812-850 |

|

90×90 |

R=3000-6000 |

L=812-850 |

|

100×100 |

R=3000-6000 |

L=812-900 |

|

110×110 |

R=3000-6000 |

L=812-900 |

|

120×120 |

R=4000-8000 |

L=800-900 |

|

130×130 |

R=4000-8000 |

L=812-900 |

|

135×135 |

R=4000-8000 |

L=812-900 |

|

140×140 |

R=4000-9000 |

L=812-900 |

|

150×150 |

R=4000-8000 |

L=812-900 |

|

160×160 |

R=6000-9000 |

L=812-900 |

|

175×175 |

R=6000-9000 |

L=812-900 |

|

180×180 |

R=6000-9000 |

L=812-900 |

|

195×195 |

R=6000-10000 |

L=812-900 |

|

200×200 |

R=6000-10000 |

L=812-900 |

Key Features

❆ 100% high quality Chile originated Copper;

❆ CuDHP, CuAg0.1, CuCrZr, CuNiBe, CuCoNiBe alloy etc

❆ Cr/Ni/NiCo/Ceramic coating etc with various shapes;

❆ state of the art milling, drilling, measuring & testing facilites etc with more than 20 years manufacturing

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for Manufacturing Companies for Copper Mould Tube Dealers - Multi Ni+Cr+Co Coating Square Mould Tube – Jinyehong , The product will supply to all over the world, such as: Frankfurt, Peru, Israel, All the employees in factory, store, and office are struggling for one common goal to provide better quality and service. Real business is to get win-win situation. We would like to provide more support for customers. Welcome all nice buyers to communicate details of our products with us!

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.