- Beijing Jinyehong Metallurgical Machanical Equipment Corp Ltd.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

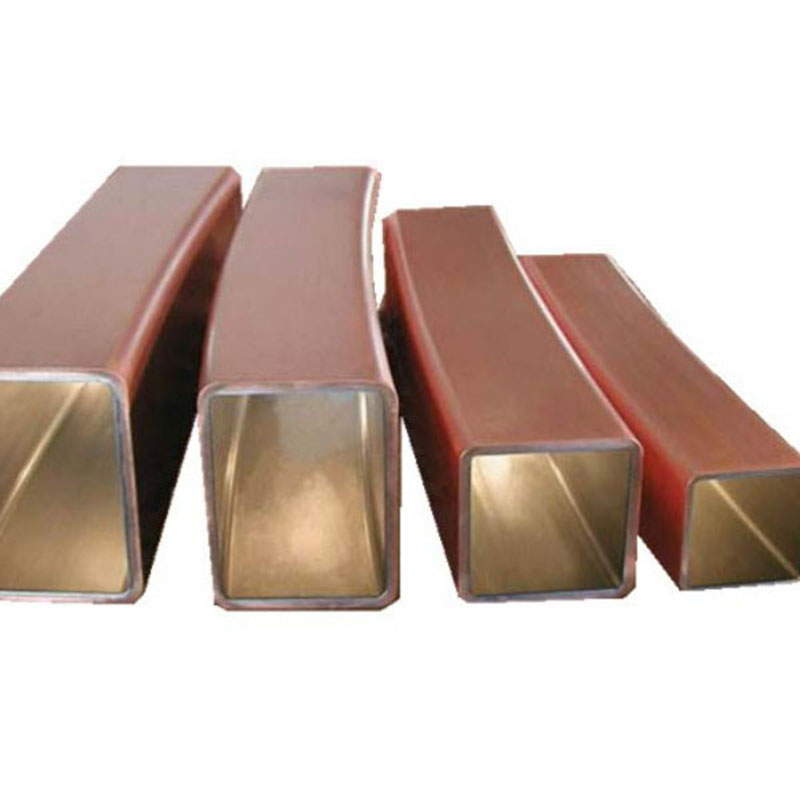

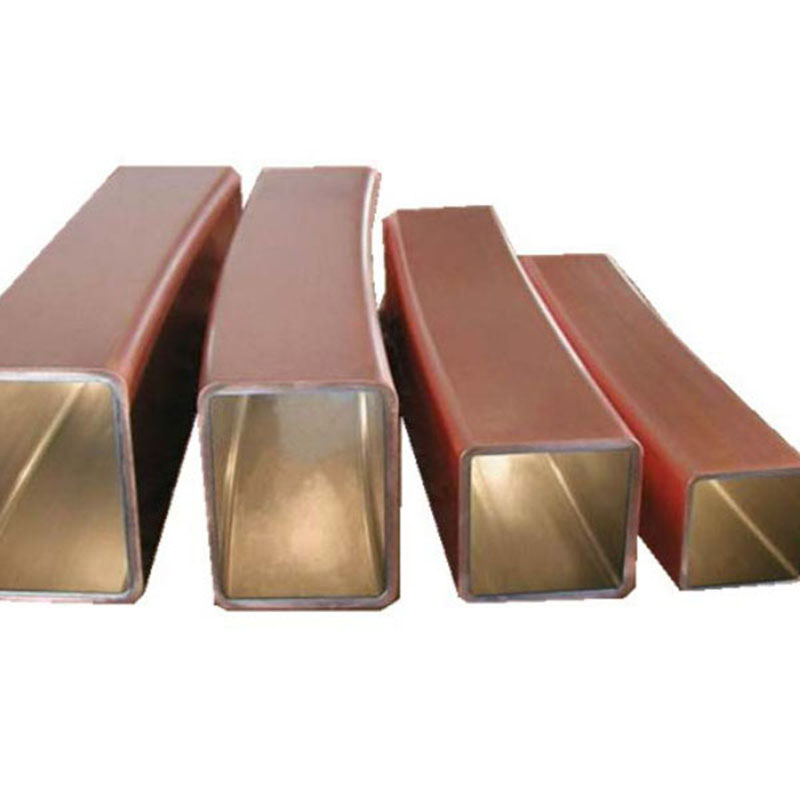

Factory source Copper Mould Tube Manufacturing Process - High Quality Rectangular Mould Tube for CCM – Jinyehong

Factory source Copper Mould Tube Manufacturing Process - High Quality Rectangular Mould Tube for CCM – Jinyehong Detail:

Specifications

Taper design: Provide different copper tube cavity taper according according to customer’s needs and casting steel environment.The main taper forms are single taper, multi-taper and parabolic taper.

Place of Origin: China

Brand Name:BJMMEC

condition: New

Spare Parts Type: Replacement Parts of Cooper Mould Tubes

Inspection Certificate: Provided

Machinery Test Report: Provided

Material: CuAg Cu-DHP CuCrZr Phosphorus deoxidized copper

Plating: Hard Chrome NiCoCr NiCr

Warranty: 1 Year

Key Selling Points: Long Service Life

Applicable lndustries: Machinery Repair Shops, Manufacturing Plant, Steelmaking …

Marketing: India, Bangladesh,Egypt,Turkey……. Showroom

Mould for Billet: CuAg CuCrZr CuDHP tubes mould

Application: Steel Plant Spare Parts

certification: ISO9001

|

Rectangular billet crystallizer copper tube specification |

||

|

Case section |

Casting machine radius |

Product length |

|

150×140 |

R=6000-8000 |

L=800-900 |

|

150×155 |

R=6000-8000 |

L=800-900 |

|

180×240 |

R=8000-9000 |

L=900 |

|

165×225 |

R=8000-9000 |

L=900 |

|

160×220 |

R=6000-9000 |

L=900 |

|

120×220 |

R=6000-9000 |

L=900 |

|

165×280 |

R=9000-10000 |

L=900 |

|

175×225 |

R=6000-9000 |

L=900 |

|

130×285 |

R=6500-8000 |

L=900 |

|

155×185 |

R=6000-8000 |

L=900 |

|

140×155 |

R=6000-8000 |

L=900 |

|

155×165 |

R=6000-8000 |

L=900 |

|

150×245 |

R=6000-8000 |

L=900 |

|

165×285 |

R=6000-10000 |

L=900 |

|

120×225 |

R=6000-10000 |

L=900 |

|

130×225 |

R=6000-10000 |

L=900 |

|

150×520 |

R=6000-10000 |

L=900 |

|

150×490 |

R=6000-10000 |

L=900 |

Our Service

(1) We can supply high quality and durable copper mould tube with most competitive price and prompt delivery.

(2) Our copper mould tube meet ISO9001 standards, high precision and meet hardness requirement, prefect taper and coated layer.

(3) We have complete facilities to process every copper mould tube.

(4) We have manufacture thousands pieces of copper mould tube every month and supply several biggest steel group in China which proved that our product is most trusted and satisfied by our customers.

FAQ

(1) Are you a factory or trading company?

Factory

(2) What is the terms of payment?

T/T L/C at sight

(3) Why should you choose our company?

a. Our company is a direct supplier.

b. With professional and technical personnel, first-class service personnel.

c. Reasonable price and best quality.

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for Factory source Copper Mould Tube Manufacturing Process - High Quality Rectangular Mould Tube for CCM – Jinyehong , The product will supply to all over the world, such as: Sri Lanka, Manchester, Italy, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.